Shenzhen ETON Automation Equipment Co.,LTD. was establised in

2007,possess more than 300 staff at present and cover an area of

more than 20000 square meters,is the largest leading manufacturer

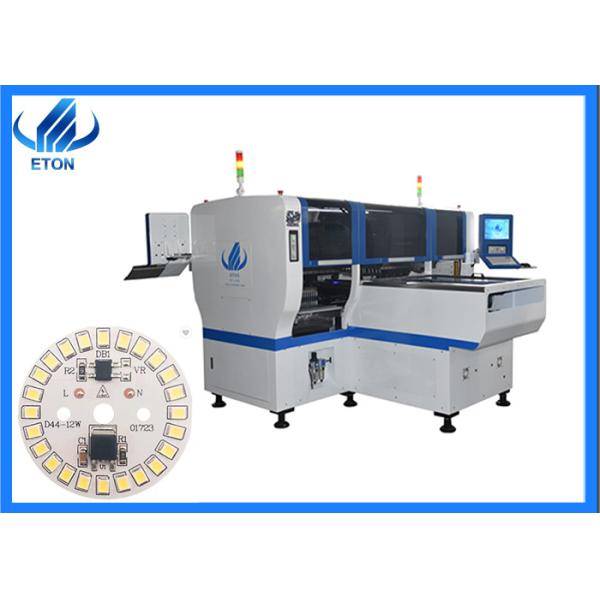

of high-speed pick and place machine and SMT machine for LED light

production and Electronic field,which is also a high-tech

enterprise and top brand well-known in China with good reputation.

ETON invented the fastest automatic pick and place machine

with speed 150000CPH,which is the fastest machine in the

world,awarded many global first technology patent,also

invented the global first machine for any length of 1M 5M 50M 100M

500M flexible LED strip,won large market in

USA,KOREA,INDIA,GERMANY,EGYPT,TURKEY,VIETNAM,TUNISIA ETC.

Since the establishment of the company, with the green and

energy-saving development trends of global illumination and rapid

development of LED industry and its requests for the manufacturing

craft, ETON has seized the opportunity and risen quickly, they have

independently researched、designed、manufactured a set of

quicker、more stable、more optimal LED fully automatic, high speed,

energy-saving chip mounter and multi-function chip mounter, which

have been highly recognized in the industry for its absolute

advantage in speed, stability and capacity, at the same time, it

have solved the offset and fling material issues when producing 1.2

meters, 1.5 meters lamp plates and wireless long FPCB and shaped

component at a high speed. ETON has passed ISO9001 quality

management system certification and has obtained more than one

hundred of patents and certificates, including for utility model,

personal invention, software copyright and so on. We have

established cooperative relationship with well-known enterprises at

home and abroad, such asMLS,OPPLE,NVC,Navigation,PAK,ETI,FSL, Home

Lighting,Yangguang Lighting, XSY, Sansi, India RK, India SURYA,

Vietnam RANGDONG, Egypt FUTEK etc..

Our products have been exported to more than 20

countries and regions, including Korea, India, Vietnam, Tunisia,

Egypt, Turkey and so on. Meanwhile, the company has created

customer service center, where records every customer and the sale

of every set of machine permanently. Its existence can timely solve

customer’s questions when using it, which truly provides the

convenience and assurance for our customers.

“High efficiency” “High quality” and “Stability” are the

core technology of ETON,technology innovation and strict quality

control,with excellent service,ETON has grown into the outstanding

worldwide brand of SMT machine with good reputation.